By Robert Urban, Executive Marketing Consultant, PaperBoat Media

What Even Is FMCG?

FMCG stands for Fast-Moving Consumer Goods. Think deodorant, soda, dog food, frozen pizza, shampoo, toothpaste—basically, the stuff people buy without needing a PowerPoint or a family vote.

It’s a high-speed game of:

- Low margins

- High volumes

- Repeat purchases

- Cutthroat shelf wars

- Constant innovation, but not too much, or you’ll confuse Susan in aisle 5

The big players? Procter & Gamble, Nestlé, PepsiCo, Unilever, and your uncle’s cousin’s private label brand that somehow outsells them all at Dollar General.

If your business moves goods like this, you need two things:

- A lean process

- A sharp, adaptable strategy

Let’s break both down, without the corporate buzzword hangover.

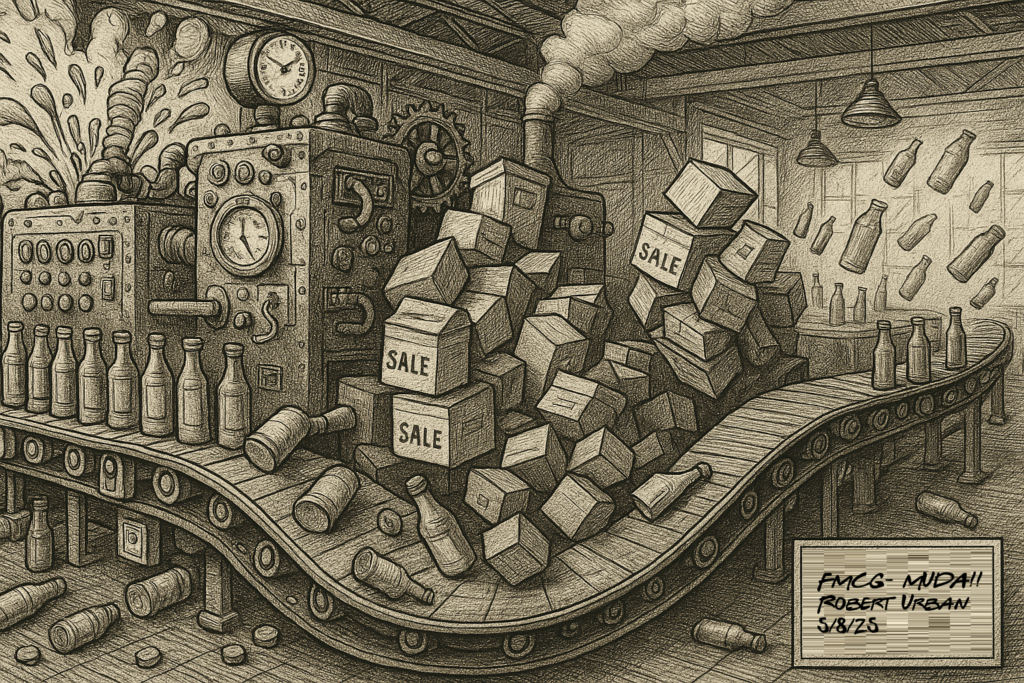

Lean Process Improvement: Not Just for Nerds in Hairnets

In FMCG, “Lean” isn’t about eating kale chips and pretending you’re full. It’s about cutting waste, speeding up production, and making sure Carl in the maintenance department isn’t the only one who knows how to fix the label machine.

What Lean Means (For Real People)

Lean is built around one core question:

“Does this step add value—or is it just burning time, money, or morale?”

That’s it.

If the answer is no, it gets the axe.

From production to packaging to pallet shipping, lean looks to eliminate the 7 deadly wastes (aka Muda, (More about this in the bottom of this post- interesting for any marketer) for those who want to sound fancy):

- Overproduction

- Waiting

- Transport

- Overprocessing

- Excess Inventory

- Unnecessary Motion

- Defects

Acronym Soup: What They’re Saying in Ops Meetings

Your average FMCG operations meeting sounds like a Scrabble game lost its damn mind. Here’s your cheat sheet:

| Acronym | Meaning | Why You Care |

|---|---|---|

| FMCG | Fast-Moving Consumer Goods | What you sell. Duh. |

| OEE | Overall Equipment Effectiveness | Your machines’ report card. Over 85% = gold star. |

| CI | Continuous Improvement | A nicer way to say “We’re never satisfied.” |

| TPM | Total Productive Maintenance | Everyone helps maintain machines, not just Carl. |

| SMED | Single-Minute Exchange of Die | Changeover time reduction. Go from hours to minutes. |

| KPI | Key Performance Indicator | The numbers you’re judged on. Choose wisely. |

| SKU | Stock Keeping Unit | Every flavor/size/package = more complexity. |

| JIT | Just-In-Time | Inventory arrives right when you need it. Nail-biting, but efficient. |

| FIFO / LIFO | Inventory rotation methods | Keep it fresh. Literally. |

| S&OP | Sales and Operations Planning | The awkward monthly marketing/supply chain meetup. |

| POS | Point of Sale | Not what you mutter when the register crashes. |

| NPD | New Product Development | Where fun ideas go to get budget cuts. |

| TQM | Total Quality Management | No crap gets shipped. Or shouldn’t, anyway. |

Strategy in FMCG: Business Darwinism

1. Know Thy Customer Like a Weird Ex

You’re not just selling body wash. You’re selling “I smell great, and also I might be dating someone.”

Use every data tool at your disposal:

- Loyalty programs

- Purchase behavior

- Heat maps

- Social listening

Find out what your consumer wants—even before they know it. Then deliver it before your competitor does.

2. Innovate… But Don’t Scare People

New products are great. Until they flop. FMCG graveyards are full of “ranch-flavored water” and “tofu jerky.”

Test quickly. Launch small. Track velocity. Kill weak SKUs ruthlessly. Double down on what sells.

Remember: Innovation without validation is just guessing with a budget.

Data Science validates choices- agile and fast pivoting must be blended with “sticking to the course of action planned”

3. Channels Matter. A Lot.

Your product shouldn’t act the same in:

- Target

- Amazon

- Instacart

- That gas station with suspicious lighting

Every channel demands a different approach to pricing, packaging, placement, and promotion. Know the battlefield.

4. Marketing Is the Engine, Not the Paint Job

If your ops team is lean, your marketing better be mean.

You can’t move fast with a bloated message. Your packaging, ad campaigns, website, SEO, and retail displays should all scream one thing:

“Buy me. I’m what you’re looking for—even if you didn’t know it yet.”

Speed-to-shelf is useless if speed-to-cart doesn’t happen.

Pro Tips for FMCG Wins

- Own Your Niche. Don’t be everything to everyone. Be essential to someone.

- Streamline SKUs. Too many options confuse customers and clog warehouses.

- Marry Ops & Marketing. They don’t have to like each other. They just need shared KPIs.

- Automate Reporting. Because nobody actually enjoys Excel dashboards.

- Audit Everything. Quarterly waste audits, shelf checks, process reviews—don’t skip the boring stuff.

I Have Replicated Success Numerous Times

FMCG doesn’t wait for you to catch up.

The shelves are brutal. The margins are tight. The trends are fickle. And one rogue tweet can tank a product line.

But if you get your systems right—both operationally and emotionally—you can build a brand that people love, trust, and habitually toss into their cart for the next 10 years.

Remember: lean doesn’t mean less. It means smarter. Faster. Sharper.

And if you’re ever overwhelmed by all the acronyms and metrics and process maps, just ask yourself:

“Is what I’m doing making it easier, faster, or better for someone to say ‘yes’ to our product?”

If not—lean in, cut it out, and move forward.

I’ve worked with global brands and scrappy underdogs. Same rules apply:

- Be fast.

- Be lean.

- Be clear.

- And never let your process get in the way of your product’s story.

FMCG is a brutal arena, but with a lean strategy, crystal-clear metrics, and a little marketing swagger—you’ll outlast the noise.

And if you ever need someone to cut through the acronym fog, realign your strategy, or just roast your current KPIs with love, you know where to find me.

Want Help With FMCG Strategy That Actually Works?

Reach out. I help brands:

- Rank higher

- Sell faster

- Waste less

- And build long-term loyalty

Rob Urban

Six-time bestselling author. PhD. Executive Marketing consultant. Marine vet.

And the guy who’ll make sure your product doesn’t just move fast—it moves smart

*Postscript: So, What the Heck Is “Muda” and Why Should You Care?

Alright, listen up. Before you close this tab and go back to yelling at your supply chain dashboard or pretending your inbox is under control, let me leave you with a little Lean wisdom from the godfather himself—Taiichi Ohno—the guy at Toyota who looked at a factory full of clutter and said, “Yeah, let’s fix this nonsense.”

In Lean thinking, Muda is Japanese for “waste.” Not like “oops, I dropped a Cheez-It,” but the systemic kind—waste that kills time, bloats cost, and buries teams in busywork with no real purpose.

The 7 Deadly Wastes (a.k.a. the original sins of inefficiency):

- Defects – Mistakes that cost time, money, and customer trust.

In other words: “We shipped it wrong again, didn’t we?” - Overproduction – Making stuff no one asked for.

Imagine baking 12 dozen muffins no one wants. Now imagine paying rent to store them. - Inventory – Unused junk waiting to be useful.

This includes that mountain of toner cartridges your office manager panic-bought in 2020. - Extra Processing – Doing more than needed.

Like inspecting something three times because you don’t trust the process you designed. - Motion – Unnecessary movement by people.

Walking across the floor 87 times a day like it’s a Fitbit challenge. - Transportation – Unnecessary movement of goods.

Shipping products in circles because Karen in logistics forgot to update the route. - Waiting – For machines. For approvals. For Kevin to finally read the damn email.

Tick… tick… tick…

But Wait, There’s an 8th Waste Now

Of course there is. Because humans ruin everything by making it more complicated.

These days, smart folks have added an eighth waste:

Underutilized Talent — Not tapping into the full potential of your people.

If you’ve got someone who could optimize your process but is stuck printing out meeting agendas and labeling folders like it’s 1996—congrats, you’re wasting brainpower.

Some experts take it even further with:

- Unsafe work conditions

- Confusion due to unclear systems

- Downtime from tech meltdowns or poor handoffs

The acronym for all eight is easy: DOWNTIME

Defects

Overproduction

Waiting

Non-Value Added Processing

Transportation

Inventory

Motion

Especially wasted human talent (Eschewed, if you’re feeling spicy)

Don’t Forget the Ugly Cousins: Mura & Muri

Lean isn’t just about Muda. It has a few evil siblings.

- Mura – Unevenness or inconsistency

Picture your production line working like a heart monitor after six Red Bulls. - Muri – Overburden or strain

When you demand more than your process (or people) can deliver. Like asking Gary in Accounting to fix the forklift.

When Mura and Muri show up to the party, Muda always follows, drunk and sloppy.

Bottom Line?

You can’t eliminate waste if you can’t see it. And you can’t see it if you’re still managing your ops with a spreadsheet older than your intern.

So reflect. Audit. Map it out. Use those fancy Lean tools and templates if you’ve got ’em.

Ask your team:

“What are we doing that adds no value, pisses people off, or slows us down?”

Then stop doing it. Immediately.

Need help identifying the waste hiding in your workflows, website, or supply chain?

I’m your guy. I’ve seen waste in Fortune 500s, startups, and everything in between—and I’ve helped cut it like a samurai chef at a hibachi grill.